|

||||

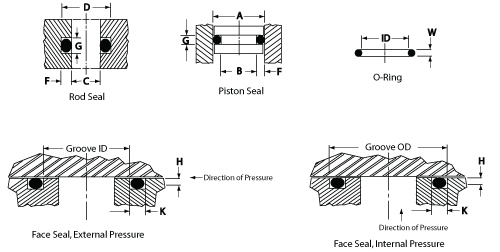

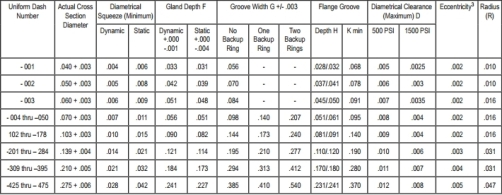

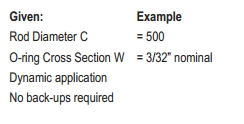

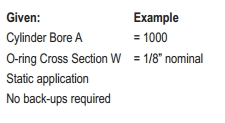

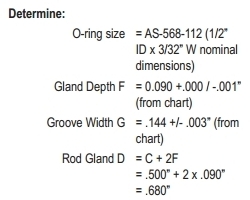

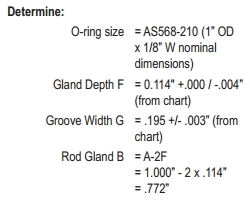

Groove Design for O-Ring Installation

Click here to Enlarge above Table Note 1. The following sizes are no normally recommended for dynamic service,

although special applications may permit there use:

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

© www.standard-rubber.com - All Rights Reserved