|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||

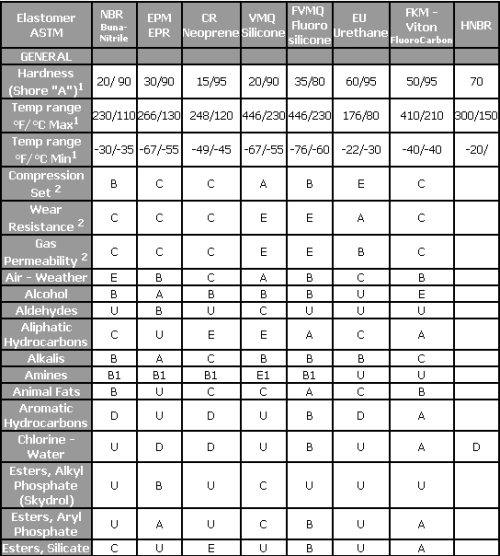

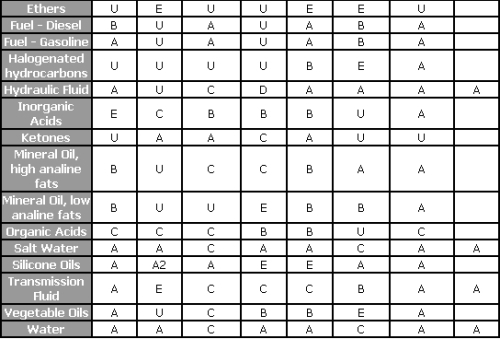

Basic Properties of ElastomersElastomer Selection Though "elastomer" is synonymous with "rubber", it is more formally a polymer that can be modified to a state exhibiting little plastic flow and quick or nearly complete recovery from an extending force, and upon immediate release of the stress, will return to approximately its own shape. According to the definition of the American Society for Testing and Materials (ASTM) for the term "elastomer" it is essential that: *An elastomer part must not break when stretched approximately 100%. *After being stretched 100%, held for 5 minutes and then released, it must retract to within 10% of its original length within 5 minutes after release. Resistance to the media As used throughout this manual, the term "media" denotes the substance retained by the o-ring. It may be a liquid, a gas, or a mixture of both. It can even include powders or solids as well. The chemical effect of the media on the O-ring is of prime importance. It must not alter the operational characteristics or reduce the life expectancy of the O-ring. Excessive deterioration of the O-ring must be avoided. It is easy, however, to be misled on this point. A significant amount of volume shrinkage usually results in premature leakage of any O-ring seal, whether static or dynamic. On the other hand, a compound that swells excessively, or develops a large increase or decrease in hardness, tensile strength, or elongation, will often continue to serve well for a long time as a static seal, in spite of undesirable test results on elastomer compounds. The first step in selecting the correct material is to select an elastomer that is compatible with the chemical environment. The Physics of Rubber Rubber is composed of long chains of randomly oriented molecules. These long chains are subject to entanglement and cross-linking. The entanglement has a significant impact on the viscoelastic properties such as stress relaxation. When a rubber is exposed to stress or strain energy, internal rearrangements such as rotation and extension of the polymer chains occur. These changes occur as a function of the energy applied, the duration and rate of application, as well as the temperature at which the energy is applied. ISO 1629 identifies approximately 25 elastomeric types. This chapter covers the various material types used in o-ring manufacture.

| ||||||||||||||||||||||||||||

© www.standard-rubber.com - All Rights Reserved